Top 5 Best Tungsten for Aluminum [January 2024 Review] MetalProfy

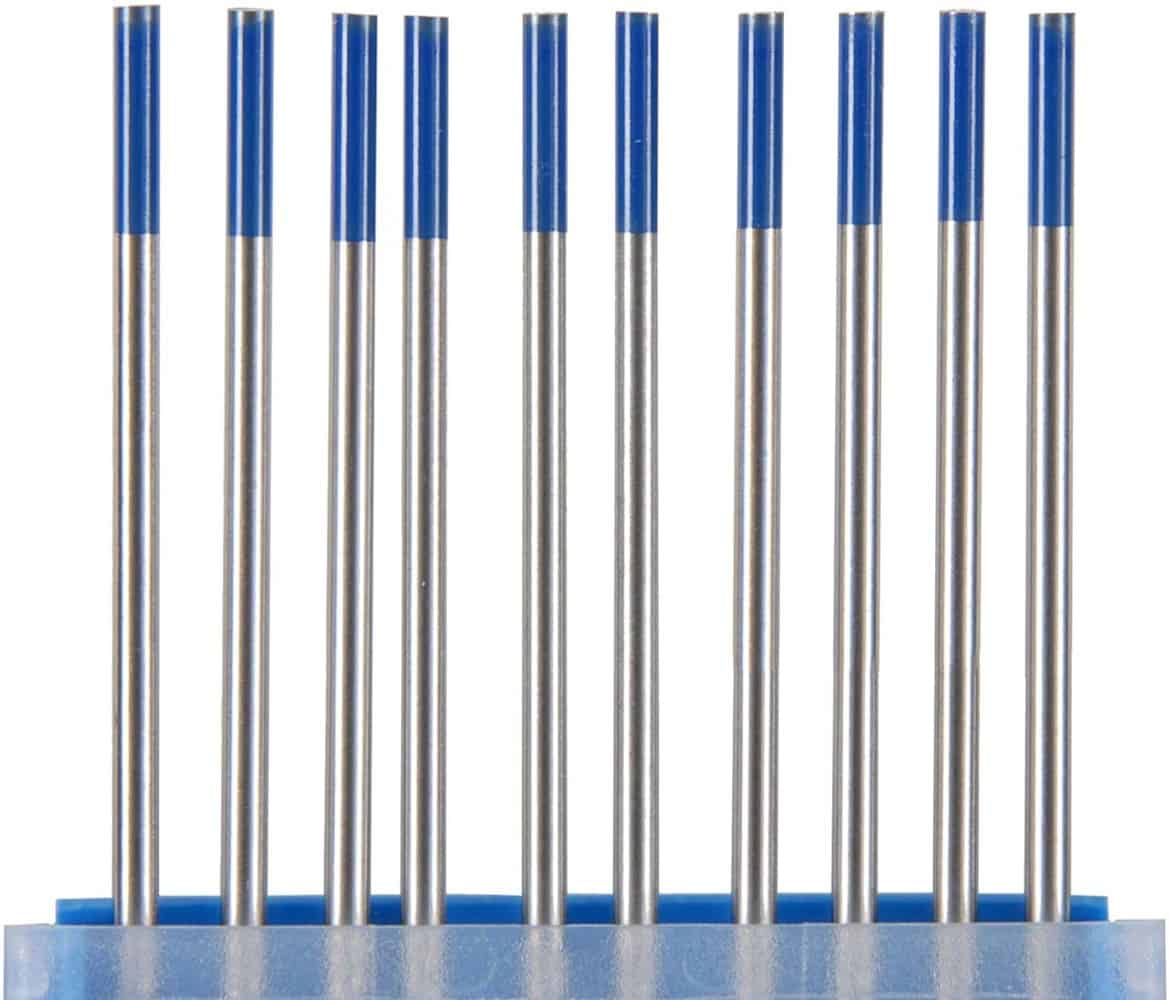

This tungsten electrode can be used in almost every field; such as aluminum alloy, copper alloy, low-alloyed steel, stainless steel. However, If you are looking for one for aluminum alloy, this one is perfect. There is a variation in size. You have to use ⅛" if you want to use for thin aluminum. There are 0.040", 1/16", 3/32" sizes.

What Color Tungsten For Aluminum Branding Mates

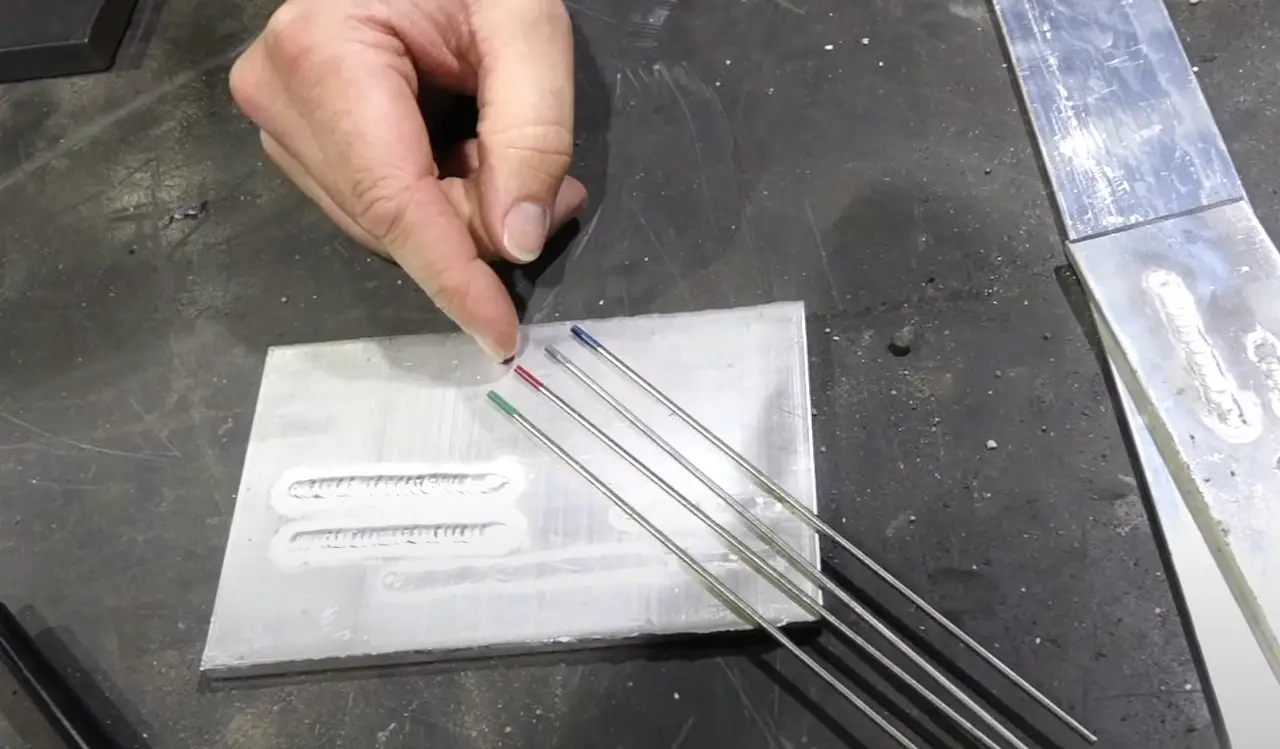

Let's talk Tungsten. What are the differences, which one is the easiest to start, which one should you buy? Baker's breaks down the differences in the top tu.

What Color Tungsten For Aluminum

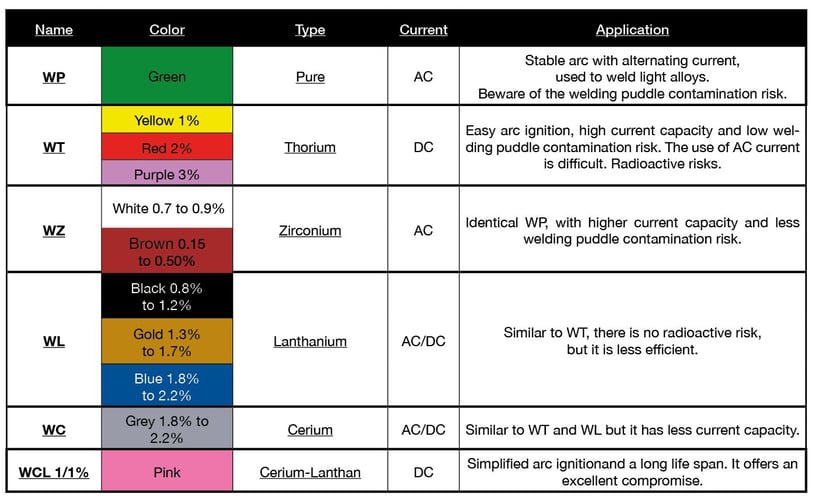

It's also a good idea to consult a tungsten selection chart (see Fig. 6) for more information when making the choice. Fig. 6: Common tungsten alloys and uses/arc characteristics. Maximize the benefits of inverter technology. The wrong tungsten selection can hamper the benefits of the advanced squarewave technology — costing money in the.

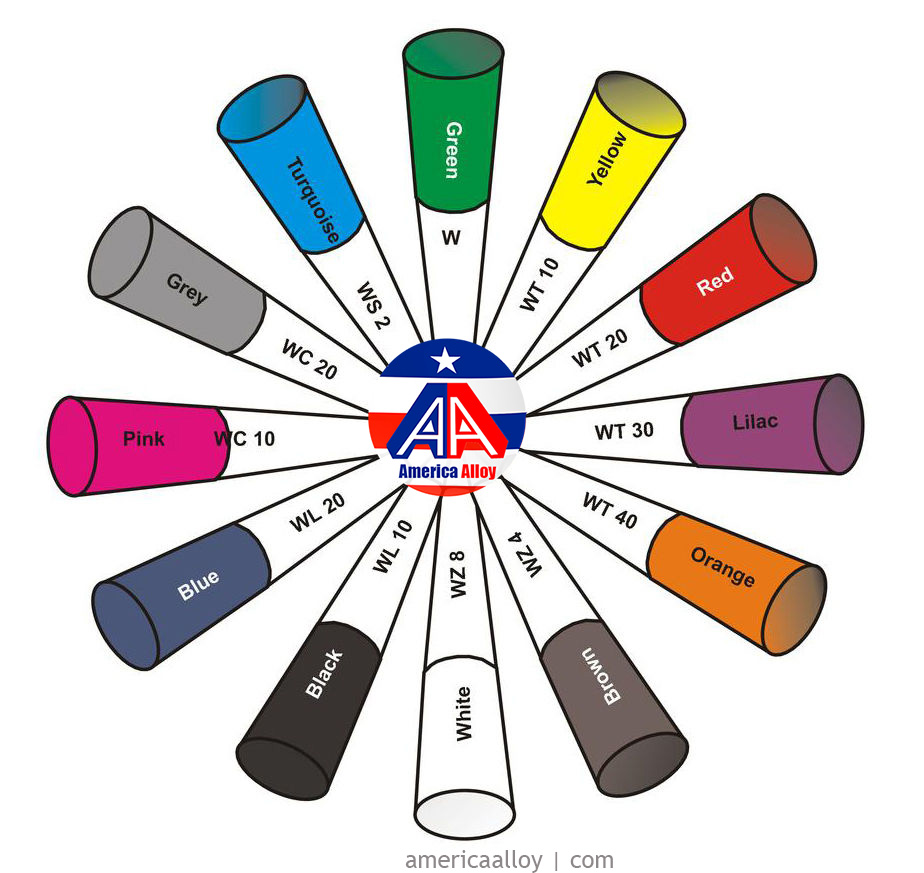

Tungsten Color Code Chart

What color tungsten to use for aluminum? For aluminum welding, you should use a Green Tip (Pure Tungsten) or a Blue Tip (2% Lanthanated). The green tip is the traditional choice for aluminum due to its suitability for AC welding, which is commonly used for aluminum. The blue tip is a more modern choice that also works well and can be easier to.

Best Tungsten for Aluminum Welding A Guide to Choosing the Right Type Aluminum Profile Blog

Lanthanated (Color Code: Gold) Lanthanated tungsten electrodes (AWS classification EWLa-1.5) contain a minimum of 97.80 percent tungsten and 1.30 percent to 1.70 percent lanthanum, or lanthana, and are known as 1.5 percent lanthanated. These electrodes have excellent arc starting, a low. burnoff rate, good arc stability, and excellent.

Best Tungsten for Aluminum Welding A Guide to Choosing the Right Type Aluminum Profile Blog

Pure tungsten was favored for aluminum and magnesium, and 2% thoriated tungsten was used for everything else.. 2% lanthanated tungsten (color-coded blue) is at the top of the list. This is a true all-purpose electrode, with excellent arc starting characteristics and the ability to transmit high current without spitting. It provides a stable.

The different types of electrodes used in orbital TIG welding

More heat goes into the tungsten electrode in AC GTAW than in DCEN GTAW. This means two things. First, you need a larger-diameter tungsten electrode to carry, for example, 200 amps AC than you would to carry 200 amps DC (see Figure 1 ). Second, if you grind the tungsten to a point and use it in AC welding, the tip rapidly deteriorates.

10 Best Tungsten For Aluminum Welding [Extensive Guide]

The various additions to the tungsten electrode serve two purposes. First, it makes the tungsten less likely to sag or droop at high temperatures. Second, it makes it easier for the tungsten to emit electrons, which gives it a higher current-carrying capacity compared to pure tungsten. Almost all direct current electrode negative (DCEN) welding.

10 Best Tungsten For Aluminum Welding [Extensive Guide]

Blue Demon 2% Ceriated Tungsten, 10/pk - TE2C. From $19.08 USD. $24.34 USD. Blue Demon 2% Lanthanated Tungsten, 10/pk - TE2L. From $14.82 USD. $18.31 USD. Blue Demon 2% Thoriated Tungsten, 10/pk - TE2T. With all of the different TIG machines around, it can be tough to figure out the best tungsten for TIG welding aluminum.

Best Tungsten for Aluminum Welding 2019 Tools Focus

3.) 2% lanthanated: 2% lanthanated electrodes can handle amperage better than other electrodes. They are coded in blue and are extremely useful in welding alloys, especially aluminum. 2% lanthanated electrodes are found suitable for thinner aluminum sheets (1/8) in AC as the amperage used is less. 4.) 1.5% lanthanated: Labeled in gold color.

Top 5 Best Tungsten for Aluminum [2020 Review] MetalProfy

The same goes for red-colored 2% thoriated tungsten. You can use orange-colored 2% ceriated tungsten for welding aluminum in AC. But for both AC and DC, you need to use the blue-colored 2% lanthanated and the gold-colored 1.5% lanthanated tungsten. There's another tungsten which is 0.40% zirconiated (brown), and it can be used in AC.

10 Best Tungsten For Aluminum Welding [Extensive Guide]

10. RADNOR 3/32″ X 7″ 1.5% Lanthanated Tungsten Electrode. CLICK FOR PRICE. This tungsten electrode may be too costly for a few stick pieces, but I didn't have it on my list without reasons. Only recommended for TIG welding, these sticks can be a non-radioactive alternative to the 2% thoriated type.

10 Best Tungsten For Aluminum Welding [Extensive Guide]

Choosing the Right Color Tungsten for TIG Welding. Each TIG welding electrode has a specific color classification that makes them easy to identify. Based on the composition of the electrode, welders will find specific applications and benefits that may work best for each electrode.. Welders can work on projects that include thin aluminum.

Tips For Selecting Tungsten Electrodes [TIG Welding]

The best color for tungsten when welding aluminum is green. Green tungsten offers the best performance and stability, as it allows for higher amperage when welding aluminum and has a lower risk of arc wander. Additionally, green offers better visibility during welding; its bright color makes it easier to see the puddle when welding in confined.

10 Best Tungsten For Aluminum Welding [Extensive Guide]

2% Ceriated (grey) These tungstens contain a small amount of cerium mixed in with the pure tungsten. Ceriated works best on DC, though it does still run on AC. It's the most popular tungsten when it comes to welding thin materials, thanks to some of its unique properties: Excellent arc starts at low amps.

What Color Tungsten For Aluminum

TIG Tungsten Electrodes Explained (with Color Chart) Selecting the right tungsten electrode is an essential part of TIG welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Correctly matching the tungsten electrode with a weld's requirements saves time and money.

- 64 Xavier St Oak Park

- Gps Track And Field 2023

- Como Se Dice Buzo En Ingles

- Musical Nursemaids Emerging From Their Shell

- 5 Letter Words Ending In Uth

- Weather In Monbulk 10 Days

- Project Runway Season 21 Release Date

- Nrlw St George Team Players

- Things To Do Near Southern Cross Station

- How To Get To Marvel Stadium