[Solved] stress (ksi) Stress Strain Curve of Steel 1045 and Aluminum 6061 in tension 120 100

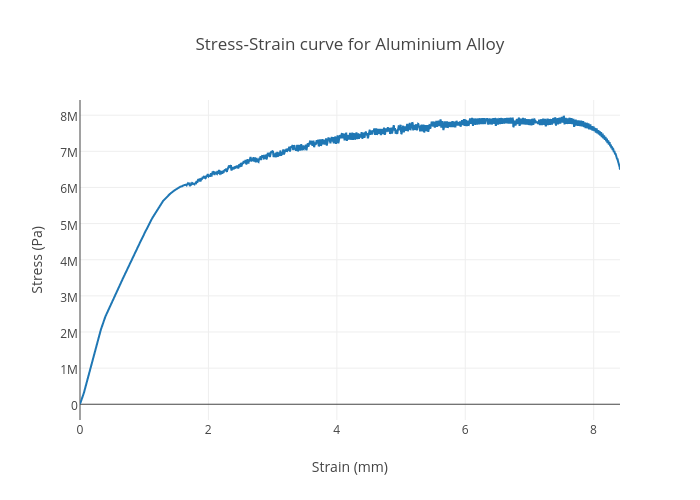

This is the stress strain curve for 6061-T6 aluminum. Notice how its stress strain curve does not exhibit a sharp yield point, but rather a gradual decrease in modulus of elasticity. Although this aluminum in fact does fail, the process is gradual and it is difficult to define a clear failure point when looking at the stress strain curve.

The true stressstrain curves of the aluminum alloy (A5052) and... Download Scientific Diagram

In the present study, use of a two-stage Ramberg-Osgood model to describe the full-range stress-strain behavior of aluminum alloys is proposed and, following careful analysis of a comprehensive database of aluminum alloy coupon test data assembled from the literature, standardized values or predictive expressions for the required input.

Stress Strain Curve Aluminum Alloys

aluminum alloys. 1.2. Modelization of Stress-Strain Curve The stress-strain curve shows, in a simple way, the deformation of a material when it is subjected to mechanical load. In this diagram, the stress is plotted on y-axis and its corresponding strain on the x-axis [39]. Tension tests provide information on the strength and ductility of.

Stressstrain curves of AA6016 T4 aluminium alloy sheet Download Scientific Diagram

Figure7:Neckinganddrawingina6-packholder. "True" Stress-Strain Curves Asdiscussedintheprevioussection,theengineeringstress-straincurvemustbeinterpretedwith

The true stresstrue strain curves of 7075 aluminum alloy during hot... Download Scientific

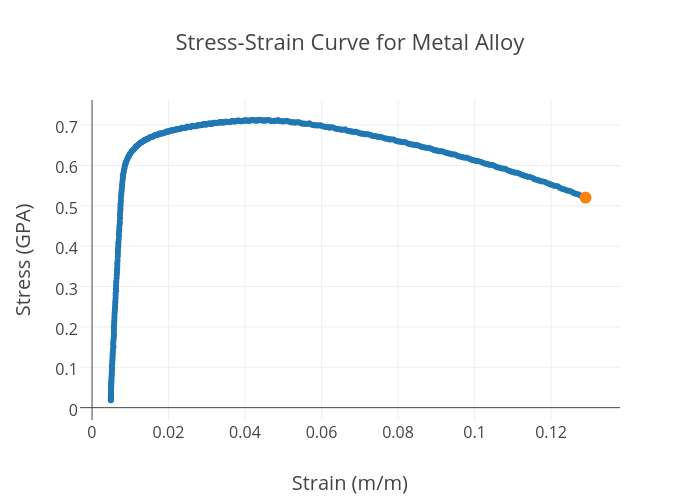

Typical ductile materials show a stress-strain curve that is very steep at the beginning (elastic zone, where the stress-strain curve is almost a straight line) and, after the yield point, the curve slope decreases (plastic zone). At one point, the slope of the curve becomes zero at the ultimate tensile strength.

True stresstrue strain curves of steel and aluminium alloy. Download Scientific Diagram

Full-Range Stress-Strain Curves for Aluminum Alloys. X. Yun, Zhongxing Wang, L. Gardner. Published in Journal of Structural… 1 June 2021. Engineering, Materials Science. AbstractAluminum alloys are being increasingly used in a wide range of construction applications owing to their sound mechanical properties, lightness in weight, strong.

True stressstrain curve of 1060 aluminum alloy Download Scientific Diagram

In this paper, complete stress-strain curves of 6082-T6 aluminum alloy were obtained with strain rate varying from quasistatic (10 −3 s −1) to moderate strain rate (100 s −1). The Johnson-Cook constitutive model was built based on experimental data. The effect of strain rate and strain on the flow stress was discussed.

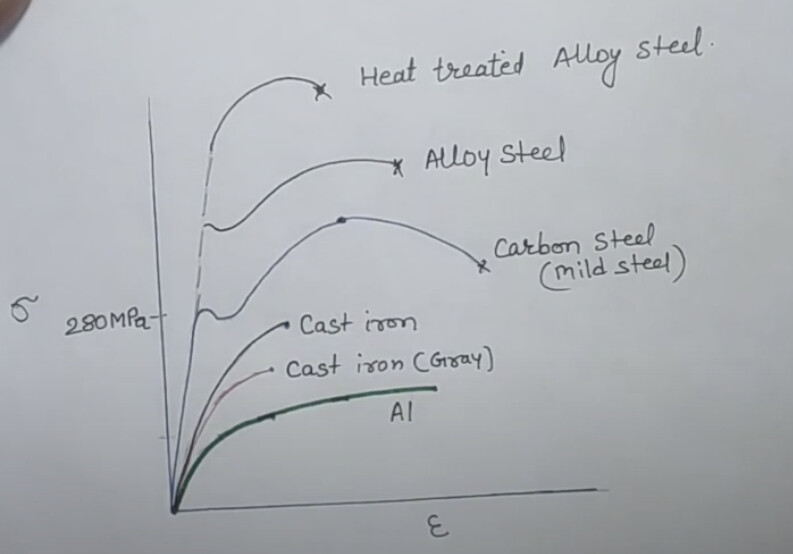

Describe/draw the stressstrain curve of aluminum vs. steel on the same graph Materials

The engineering measures of stress and strain, denoted in this module as σe and εe respectively, are determined from the measured the load and deflection using the original specimen cross-sectional area A0 and length L0 as. σe = P A0, ϵe = δ L0. When the stress σe is plotted against the strain ϵe, an engineering stress-strain curve such.

Comparison of stressstrain curves for aluminum and steel materials. Download Scientific Diagram

Full-range stress-strain (SS) curves are crucial in understanding mechanical properties of a material such as the yield strength, ultimate tensile strength, and elongation. In this study, a full-range SS-curve was nondestructively estimated by applying machine learning to the ultrasonic amplitude-scan signal propagated through the material.

StressStrain Curve for Metal Alloy scatter chart made by Perlatmsu plotly

The stress-strain curves in this data set are representative examples of the behavior of several cast alloys under tensile or compressive loads. The curves are arranged by alloy designation. Each figure cites the original source of the curve and provides pertinent background information as available.

Stress Strain Curve For Aluminum 6061 T6

Accurately predicting stress-strain curves is essential for understanding the plastic behavior of metallic materials. This study investigates the effectiveness of machine learning (ML) methods in predicting stress-strain curves for aluminum alloys at different temperature levels. Specifically, three ML techniques, Gaussian process regression (GPR), neural network (NN), and boosted trees.

True stressstrain curve of 5052O aluminum alloy Download Scientific Diagram

the stress-strain curve and a straight line with slope of E and beginning at 0.002 (0.2%) on the strain axis. The most satisfactory definition of yield strength for aluminum alloys and many other materials. Note: At this definition of yield, the plastic portion of the strain is 0.002 and the elastic portion of the strain is . σ y σ σ y E E 1.

Stressstrain curve for 7075 Aluminum alloy. Download Scientific Diagram

5 The determination of n requires, in addition to the conventional yield stress (i.e. 0.2% proof stress), the choice of a second reference point on the stress-strain curve.

Stressstrain relationships for typical steel and aluminium alloys. Download Scientific Diagram

curves obtained from 56 sources and covers five common aluminum alloy grades, namely. 5052-H36 ,6061-T6, 6063-T5, 6082-T6 and 7A04-T6. The developed model is shown to be. more accurate in.

Stressstrain curves of the 0.1 mm aluminum foil comparison in... Download Scientific Diagram

Tensile and Microindentation Stress-Strain Curves of Al-6061 Weaver, Jordan S.; Khosravani, Ali; Castillo, Andrew; Kalidindi, Surya R. Recent spherical microindentation stress-strain protocols were developed and validated on Al-6061 (DOI: 10.1186/s40192-016-0054-3).. Relatively new aluminum alloys included are 7033, Al-Li 8090 and 2090.

Stress Strain Curve Aluminum Alloys

Recently, a high pressure torsion testing method was developed to measure stress - strain curves in a super large strain range, e.g. over 10. In this paper, through improvement of the method to measure strain rate and temperature dependencies, SS curves of pure aluminum were successfully measured in a temperature range of 298 - 573 K (25 - 300 ºC) and a strain rate range of 0.02 - 2.0 /s.

- 26 Monaro Street Seven Hills

- Motorbike Tyre Pressure Monitoring System

- How Do You Spell Glenda

- Boney M Oh My Lord Lyrics

- 60 Douglas Avenue South Perth

- Cast Of Swallows And Amazons 2016

- Brad Williams Movies And Tv Shows

- Florence And The Machine Tour 2023

- What To Do Murray Bridge

- 6 Waterfront Place Port Melbourne