Double Block & Bleed Valves Alco Valves UK Valve Manufacturers

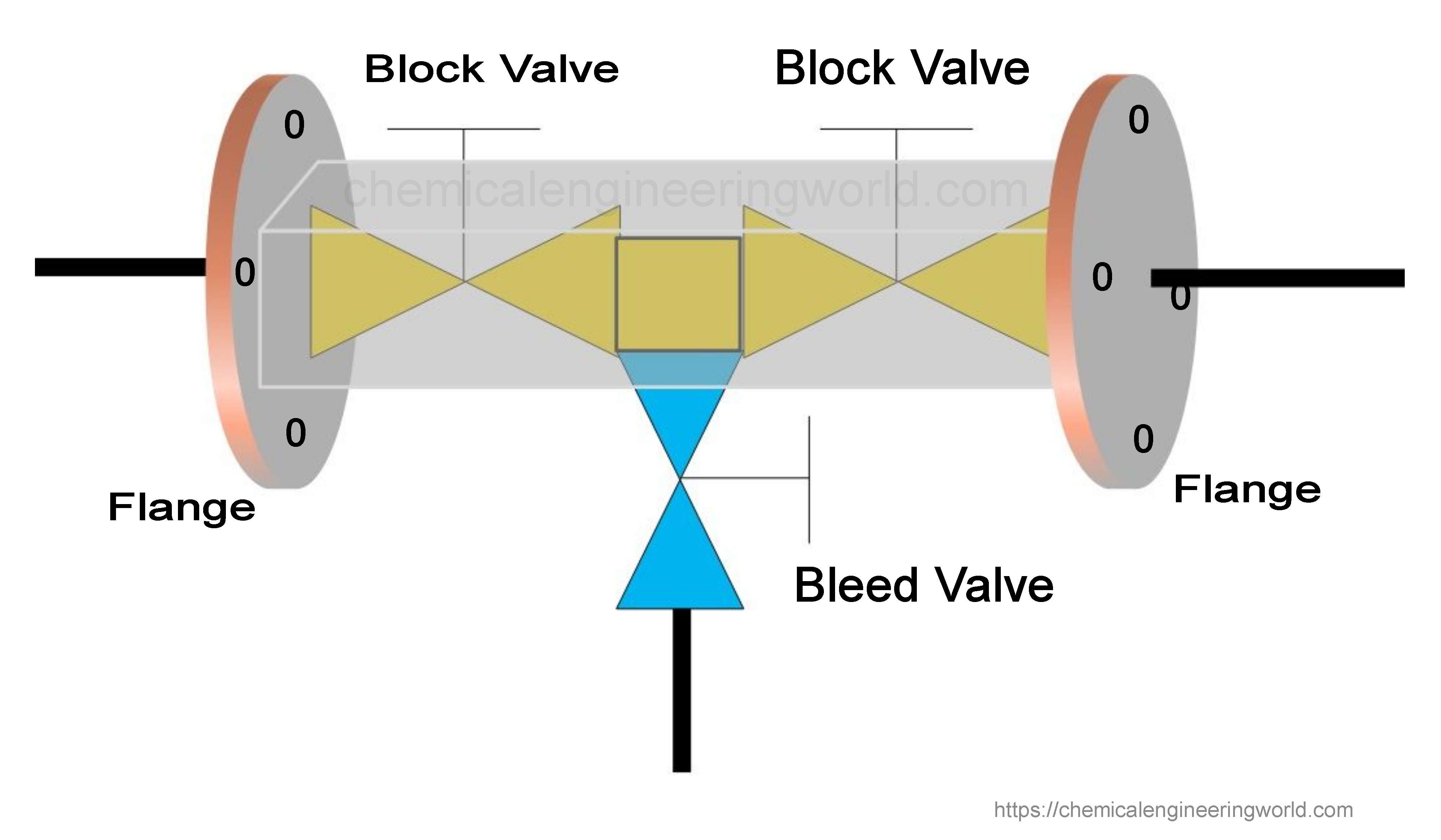

The real meaning or use for a Double Block and Bleed valve (DBB) is in isolating the flow of media in a pipe using three valves. The three valves are made up of two block valves and one bleed valve. Depending on the process that the DBB is to be used in such as temperature and pressure, the assembly and materials will differ. If the valve is to.

Double Block & Bleed Valves (dualsafe valves) Hanwel Process

Under API standards, a DBB valve is "a single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve, with a means of venting/bleeding the cavity between the seating surfaces". To OSHA, a DBB valve is "the closure of a line, duct, or pipe by closing and locking or tagging.

VALVE Double Block and Bleed 2 600 RF PARKER 316 Stainless PBY220B32F600FN SPW Industrial

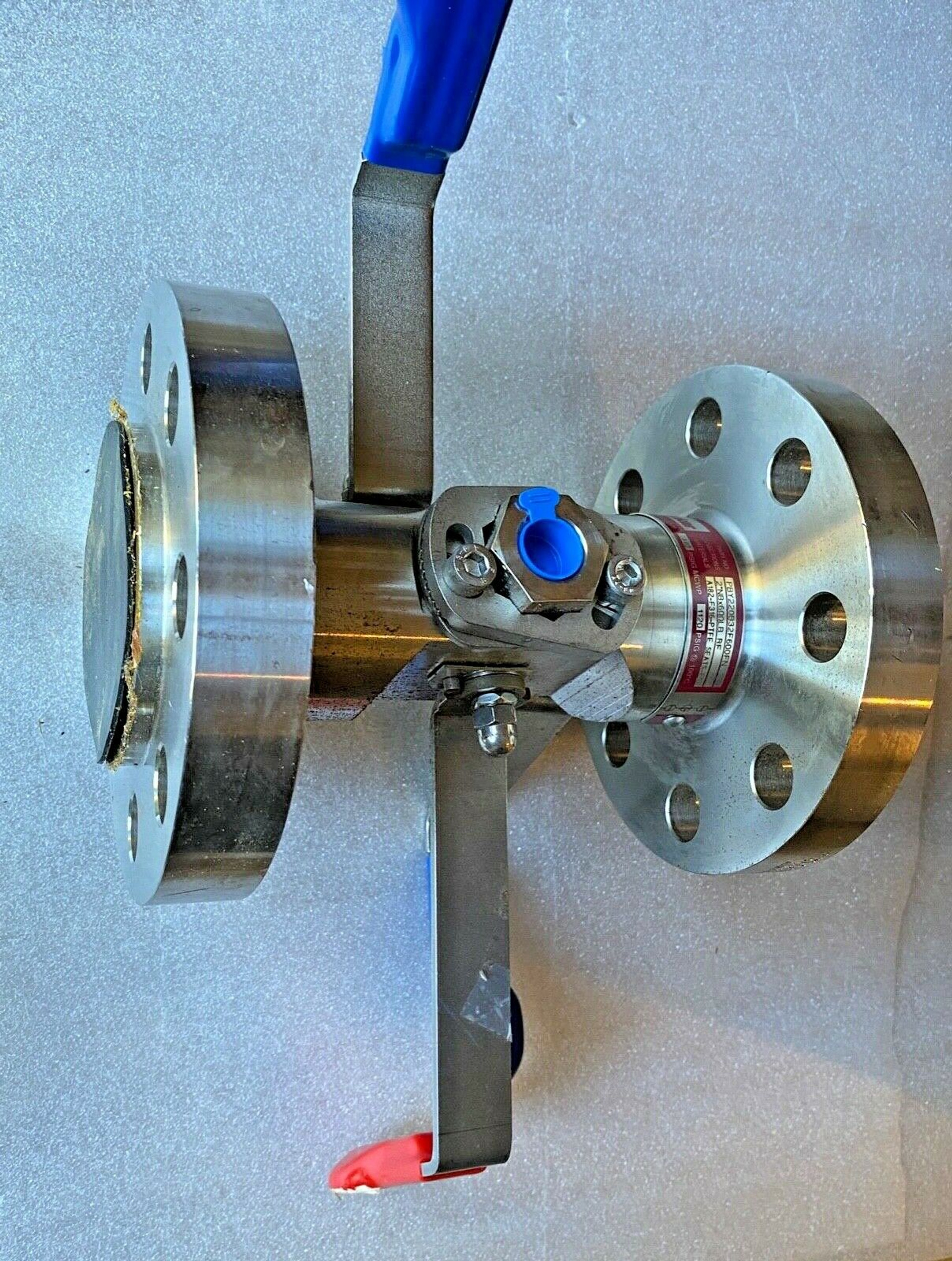

IPT series valves featuring double block and bleed configurations provide double positive isolation, allowing MRO activity, sampling, leak checks, or other crucial tasks to be conducted downstream. The IPT series trunnion-style ball design provides a consistent seal across a full range of pressures, even if systems are depressurized and.

Block and Bleed Valve Function Chemical Engineering World

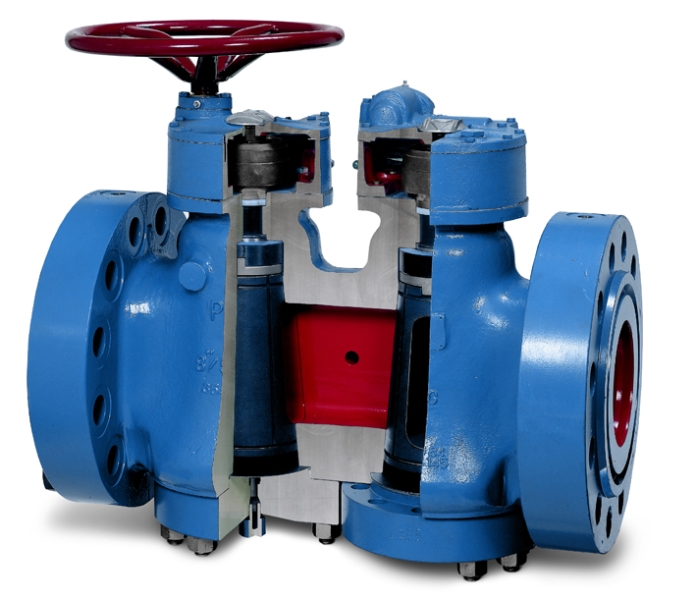

Double-block-and-bleed valve (DBB) is defined by API 6D as a "single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of venting/bleeding the cavity between the seating surfaces.". When just one side is under pressure, this valve does not have positive.

Double block and bleed Valve 3/4 inch Class 600

A short video depicting how a double block and bleed valve operates.http://www.petersmithvalve.co.uk/valves/double-block-bleed/

Introduction to Double Block and Bleed Valve System

Double block and bleed valve (DBB valve) refer to two individual block valves linked together with a bleed valve in between, used to check for leakage. While this remains their most frequent use case, DBBs can also be utilized for other sealing requirements and quickly adapt to changes in fluid system pressure or flow needs.

Double Block and Bleed Plug Valve The Piping Engineering World

API 6D defines a double-block-and-bleed valve (DBB) as a "single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of venting/bleeding the cavity between the seating surfaces.". The 2008 note points out that this valve does not provide positive double.

BBV DOUBLE BLOCK & BLEED VALVE Winters Instruments

The term Double Block and Bleed initially meant two separate block valves with a pipe and bleed valve between the valves to check for leakage. The Western Valve DAN-EX is an accepted Block and Bleed Valve (DBBV) as it has two independent seating slips that are mechanically expanded against the body seat by the downward movement of the tapered plug.

Double Block and Bleed Animation for Industrial Valve Company YouTube

Double block and bleed Valves operate on the principle that isolation can be achieved from both the upstream and downstream process flow / pressures. This is achieved by two ball, gate, globe, needle, etc. Valves placed back to back, with a third "isolatable" Valve in the centre cavity. Once isolation has been achieved in one or more of the.

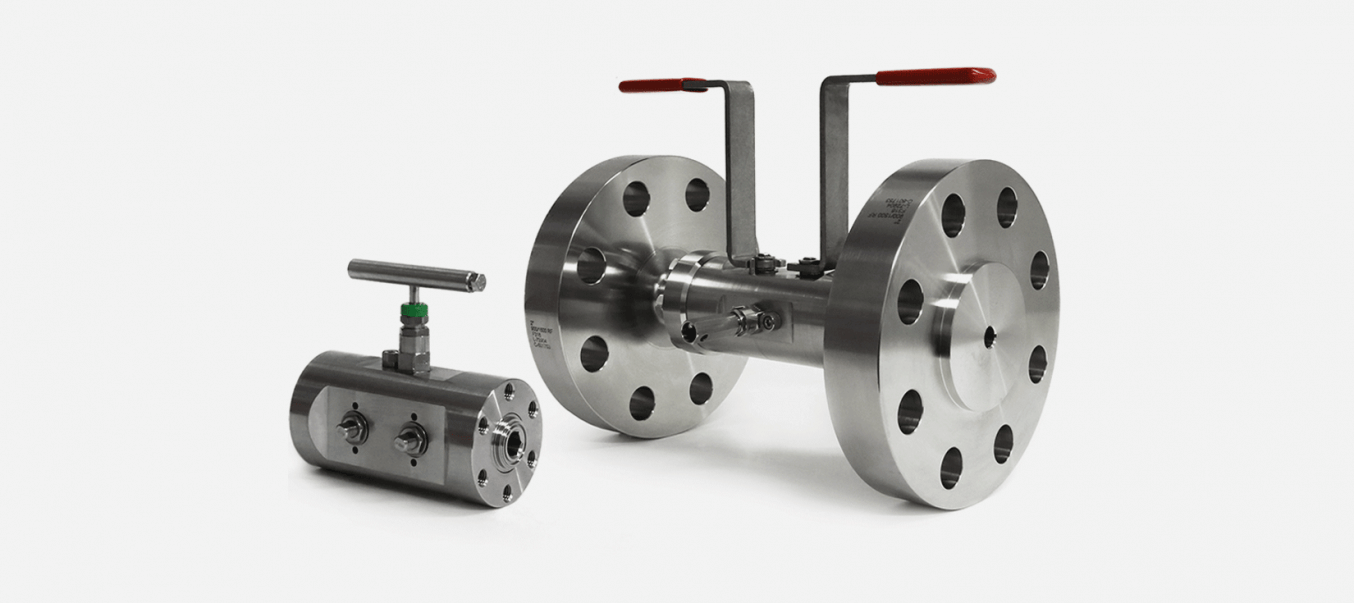

Modular valve ProBloc TP Series Parker

A double block and bleed valve is like having three valves in one. API 6D defines a double block and bleed valve as a "single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of vending/bleeding the cavity between the seating surfaces."

Double Block and Bleed Ball Valve, Double block and bleed ball valves Relia Valve

To properly understand double block and bleed valves, one must first understand the definitions established by API regarding double block and bleed (DBB) vs. double isolation and bleed valves (DIB). Double block and bleed as defined by API 6D is a "single valve with two seating surfaces that, in the closed position, provides a seal against.

Double block and bleed valve introduction News China Ball valve manufacturer,factory and

How does a double block and bleed work? A double block and bleed is often used for a more positive isolation of a process fluid from other equipment. It normally consists of two block valves (Valves 1 and 2 in the pictures) and a bleed valve (Valve 3) to a safe location, consistent with local environmental regulations. When the process fluid is.

Double Block & Bleed Valves

How to choose a Double Block and Bleed Valve: https://www.budenberg.co.uk/blog/what-is-a-double-block-and-bleed-valveOrder your Double Block and Bleed Valves.

Single and Double Block & Bleed Valves DKLok Canada

The mechanical wedge action of a double block and bleed plug valve, such as the Cameron GENERAL Twin Seal double block and bleed plug valve, firmly compresses both the upstream and the downstream seals against the valve body, requiring no help from the line pressure to effect a positive seal. Double block and bleed plug valves, which are used.

Double Block Bleed Valve at Rs 7900/piece(s) Double Block Bleed Valve ID 9990214812

A double block and bleed valve is like having three valves in one. API 6D defines a Double Block and Bleed Valve System as a "single valve with two seating surfaces that, in the closed position, provides a seal against pressure from both ends of the valve with a means of vending/bleeding the cavity between the seating surfaces.". OSHA.

Double Block & Bleed Valves Monoflange, PM & PCF DBB Series

The advantages of double block and bleed valve can be summarised as follows: Compact design. Provides sealing against pressure from both the upstream and downstream ends of the valve. The capability of venting the cavity in between the block valves. Around 60% savings in weight and 70% savings in installation time.

- What Does E M Stand For

- Chloe Bennet And Logan Paul

- Temperature In Greek Islands In September

- 12 Brian Street Fairy Meadow

- Naruto Movie Clash In The Land Of Snow

- Law And Order Special Victims Unit Season 6

- Papua New Guinea Interesting Facts

- Hotels In Central Auckland New Zealand

- Man City Real Madrid Players

- Can U Feel It Lyrics